RC модел U.S.C.G.C Acushnet - 7

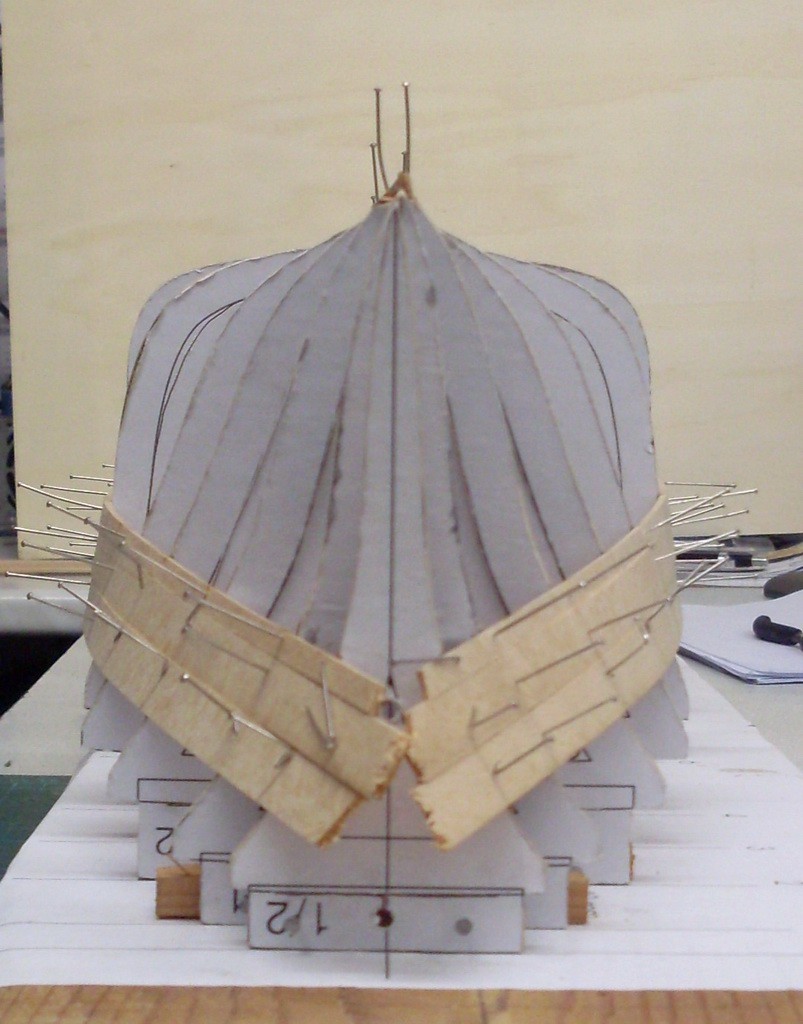

Precision drilling begins. Two holes need to be drilled for the deadwoods and two holes for the rudders. I mark and drill 4 F8 holes because I will use ready-made F9x240 deadwoods with Teflon bushings. Additionally, I solder 1 connector to the deadwoods. Later, I will also add 1 hose 7-8 cm through which a little oil will drip for better sealing, because the deadwoods and the entire valolinia are completely under water. So that there are no unnecessary vibrations during the movement of the model, the deadwood should be on two supports, not cantilever only on the board. For ease, I use the inner part of the 13th rib. I am drilling 2 F4mm holes which I will widen to F9 for the deadwoods to pass through.

MOTORS.

The next VERY IMPORTANT point is the locations of the electric motors. They should be able, if possible, to be easily serviced, moved and removed. For me, this mounting and dismounting of the motors will not be very easy, because the deck opening under the wheelhouse will be about 8 x 17 cm. The shafts will be quite long, 45-50 cm, but I think this will not be a problem.

The motors I will use are Turnigy LD3730A-1000. Three phase brushless outrunner and I'll have plenty of power to spare. I'm thinking of running them on two lipo cells if I have to even re-wind them for lower RPMs. I mount the motors on a common plate, plywood 4mm 6-layer strong and dense, not second-hand, just before the 8th rib. It will be most convenient for service there.

Clutch.

I decided to put flexible CNC carriages. I think they will have less vibration with those long shafts.

Before I epoxy the deadwoods and the motor plate I assemble the whole movement to make sure everything is ok with alignment and accuracy.

Leave a comment